If you've ever stood on a jobsite with a piece of string and a tape measure, chances are you've heard somebody mention the 345 rule—sometimes called the 3-4-5 triangle. It's an old-school builder's trick, but it still pops up in just about every commercial build. The whole idea comes down to this: you want a guaranteed way to check if something is truly square, with no fancy gadgets or guesswork needed. Being off by even half an inch can mess up doors, walls, or even entire layouts, especially when you're dealing with tight deadlines and expensive materials.

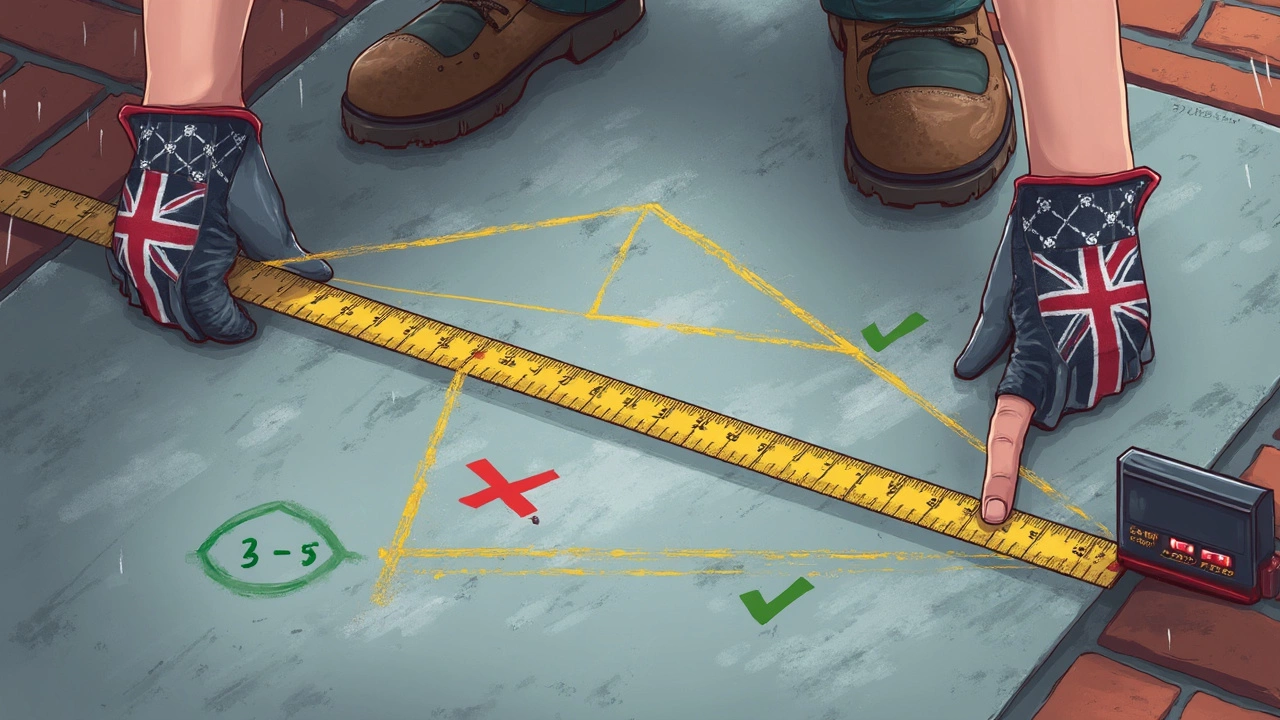

Here's the cool part: the 345 rule is all about simple numbers anyone can remember. Just measure three feet on one side, four feet on the other side at a right angle, and then the diagonal between those spots should be exactly five feet. Nailed all three? Congrats, you've got a perfect right angle. This trick works at any scale—multiply up for huge walls or break it down for smaller details.

- What Is the 345 Rule, Really?

- The Science Behind the Rule

- Why Pros Swear By It

- Common Pitfalls and Fixes

- Handy Tips for Everyday Builds

What Is the 345 Rule, Really?

The 345 rule is one of those things that never goes out of style in commercial construction. It’s basically the go-to way to check if two lines or edges are set at a true right angle (90 degrees). The whole trick comes from the numbers in its name: three, four, and five. It’s rooted in basic geometry—the Pythagorean theorem—and it has nothing to do with luck or eyeballing.

Here’s how it works in practice. Let’s say you’re laying out the foundation for a building. You need exact corners, or everything else will be off. You measure one side at three units (could be feet, meters, or whatever scale works for your site). Then you measure the next side at four units at a right angle to that. Finally, the diagonal connecting the two points you marked should be exactly five units. If it isn’t, your corner isn’t square.

Most folks use this with feet—so, 3 feet, 4 feet, 5 feet. But this scale works at any size, which is why it’s so handy. Laying out a big warehouse? Go 30, 40, and 50 feet. Doing a tiny form for a footing? Go 6, 8, and 10 inches—the math never changes, just the measurements.

This rule is used on all kinds of jobs: making sure concrete forms are square, checking wall corners, marking lines for flooring, and even before drilling or cutting materials. It’s quick, cheap, and doesn’t rely on expensive equipment or software.

If you don’t use the 345 rule, you’re pretty much asking for headaches later. Stuff won’t line up, doors will bind, walls will look crooked, and costs can climb fast because of fixes. That’s why every experienced builder keeps this one in their toolbelt—alongside the actual tape, chalk, and stakes they use every week.

The Science Behind the Rule

This whole setup is built on the good old Pythagorean theorem that a lot of us learned way back in school. Here’s the short version: in any right triangle, the two sides meet at a 90-degree angle, and the diagonal (hypotenuse) squared equals the sum of the other two sides squared. So, if one side is 3 feet and the other is 4 feet, the diagonal should be 5 feet because 3² + 4² = 9 + 16 = 25, and the square root of 25 is 5.

Why does this matter on a real jobsite? Because it’s an easy, proven way to double check you’re putting up walls, forming concrete, or installing anything at a perfect right angle. The 345 rule is reliable, repeatable, and doesn’t require expensive lasers or apps. Here’s how the math looks compared to common field measurements:

| Side A (ft) | Side B (ft) | Diagonal (ft) |

|---|---|---|

| 3 | 4 | 5 |

| 6 | 8 | 10 |

| 9 | 12 | 15 |

If you need to make a bigger triangle for a bigger space, just double or triple those measurements. Need a 9-foot by 12-foot right angle? The diagonal should measure 15 feet. Always check these numbers. It’s easy to mix them up, especially in busy commercial construction spots where distractions are everywhere.

Another thing that makes the 345 rule a superstar: it sidesteps a ton of 345 rule headaches that come from “eyeballing” right angles—which never works under pressure. Instead, crews can pull this trick out on the fly and get repeatable results that keep the whole build square, straight, and up to spec. You get predictable results every single time, which means fewer surprise fixes later and a smoother handover at the end.

Why Pros Swear By It

Ask any veteran foreman or site manager, and they’ll tell you the 345 rule is one of those things you just can't skip—especially when stakes are high and accountability matters. Pros count on it because it takes the human error out of "eyeballing" square corners. Sure, fancy laser levels and digital tools exist, but when power is out or gear gets dropped, you need a backup you trust every single time.

The real kicker? The 345 rule is fast. Teams don't waste time fumbling with apps or double-checking with blueprints. They measure, snap their chalk lines, and move on because they know math doesn’t lie. It keeps concrete forms straight, steel framing plumb, and finish work looking clean.

Data backs this up. Surveys from commercial contractors show jobs that use the 345 rule for every major layout have up to 33% fewer costly corner corrections than jobs that rely mostly on eye or digital checks. That translates to real savings—not just in materials, but in labor hours no one wants to waste.

| Aspect | 345 Rule | Other Methods |

|---|---|---|

| Time to Check Corner | 1-2 minutes | 3-8 minutes |

| Error Rate (Avg.) | Less than 1% | Up to 8% |

| Equipment Needed | Measuring tape, string | Laser, apps, specialty tools |

Pros also like that it's scalable. Need a 9-foot by 12-foot corner? Use the same 3:4:5 pattern, just multiply each number by three. Doesn't matter if it’s a small storage shed or laying out a full warehouse—no retraining needed. Every crew can use the same trick without confusion, which really pays off on big sites with a lot of moving parts.

This rule has actually been around since ancient Egypt. Builders have trusted it for thousands of years—kind of says everything about how reliable it is. When margins are tight and there’s no room for mistakes, the 345 rule helps pros get their corners spot-on without drama.

Common Pitfalls and Fixes

Even though the 345 rule keeps things simple, mistakes still happen all the time on commercial jobsites. One of the most common issues? Sloppy measuring. If you’re eyeballing instead of using a tape for each side, you can be out by an inch or more—and that adds up fast. That’s especially true when you scale the rule up to 6-8-10 or 9-12-15 across long walls. Even a tiny error at the start means you’re fighting crooked lines all the way down a corridor.

Another classic mess-up: not keeping the tape perfectly flat. When the tape sags or the string bows, your diagonal gets longer and throws the angle way off. Always keep it tight and flat on the surface you’re working on, or those right angles won’t be right at all.

There's also the rookie move of skipping the cross-check before pouring concrete or locking walls in place. Once it’s set, fixing it means extra labor, material waste, and delays off the schedule. Pros always double-check their layout at least twice before making anything permanent. That habit saves thousands in rework costs and keeps your punch-list shorter.

- Double-check each measurement with fresh eyes. Sometimes a quick re-measure will catch a simple mistake you missed when you were tired or rushed.

- Use brightly colored chalk lines or spray paint, so you can spot your lines in low light or if debris covers your marks.

- If the diagonal isn't matching the rule, check the foundation or floor for bumps or dips that could be throwing your numbers off. Uneven ground is a sneaky culprit.

| Mistake | How to Fix It |

|---|---|

| Diagonal off by more than ¾" | Re-measure both sides and stretch the diagonal again with both ends anchored |

| Lines aren't visible or get bumped | Mark with chalk paint and protect with cones or markers |

| Doing the 345 on uneven ground | Level the base or use a laser level before measuring |

| Forgetting to cross-check both diagonals (for rectangles) | Measure both diagonals to confirm the layout is square from both corners |

One more thing: always carry backup gear. Tape measures break, and chalk washes away in the rain. More than one builder has wasted half a day because something as basic as a broken tape stalled the layout.

Handy Tips for Everyday Builds

The 345 rule might sound old-school, but it's a lifesaver for commercial projects where being off by even a little can cost you both time and money. Here’s how to use it like a pro, whether you’re squaring up a giant slab or double-checking a door frame.

If you’re working solo, grab a chalk line and mark your three measurement points before you start. For bigger crews, make sure everyone’s on the same page with the measurements to avoid the "I thought you meant millimeters, not inches" mess. And don’t just eyeball it—use a sharp marker, hold your tape tight, and don’t round up or down. It matters.

"Before pulling out the laser, our teams always mark out the 3-4-5 to double-check. It's simple and it works, especially on busy sites where things move fast." — Alex Gutierrez, Project Manager, Turner Construction

For things like footings, walls, and pads, try multiples: 6-8-10, 12-16-20. This spreads your checks out and makes small mistakes easier to spot. Toss in a metal framing square if you’re working on tight corners—sometimes a fast check at both ends saves you from headaches later.

- Always measure from the same reference point each time.

- Measure at ground level when possible. Flooring and debris can shift things up top.

- Double-check with both tape and diagonals if you’re squaring up big sections.

- If your numbers don’t add up, check for board warps or twisted forms before re-measuring.

- Mark your points with paint or chalk for easier re-checks down the road.

Here’s some quick data on mistakes that eat up time on site:

| Common Error | Avg. Time Lost (hrs/week) | Typical Cause |

|---|---|---|

| Layout not square | 4.5 | Improper use of 345 rule |

| Re-make of forms | 3.2 | Missed diagonal check |

| Door/frame binding | 2.1 | Slightly off-square corners |

One last thing: Don’t be embarrassed about triple-checking with the 345 rule, even on sites packed with digital gadgets. It’s fast, reliable, and if you mess it up, you’ll hear about it, guaranteed. Stick to the basics for fewer do-overs and a lot fewer headaches.