Heavy Civil Construction Cost Estimator

Estimated Project Cost

Base cost: £0

Contingency: 15%

Environmental impact: Low

Location factor: Low

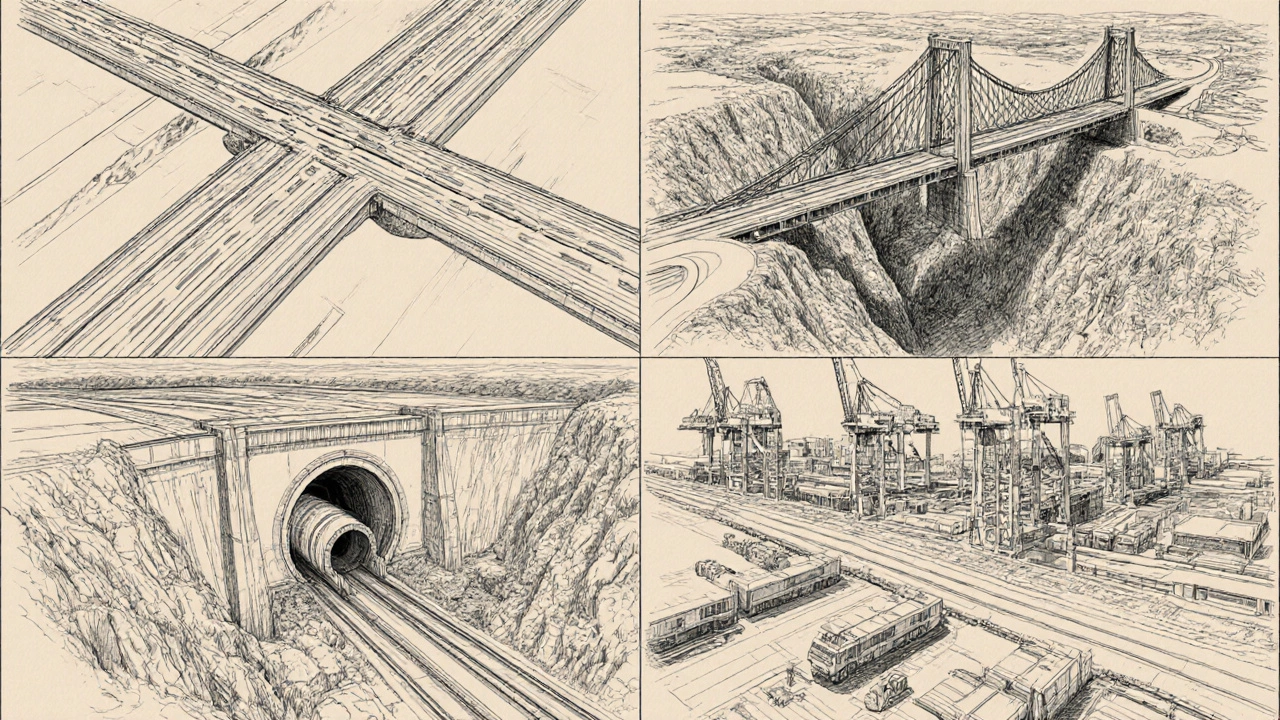

When you hear a massive bridge span, a deep tunnel cutting through a city, or a towering dam holding back a reservoir, you’re looking at heavy civil construction. Unlike smaller‑scale jobs like a home remodel, heavy civil involves huge public works that move people, goods, and water on a regional or national level. This guide breaks down what counts as heavy civil, why it matters, and how the industry keeps those colossal projects on track.

Key Takeaways

- Heavy civil construction covers large‑scale infrastructure such as highways, bridges, tunnels, dams, airports, and rail networks.

- Projects are typically funded by government or public‑private partnerships and require extensive planning, environmental reviews, and regulatory compliance.

- Core materials include high‑strength concrete, structural steel, and massive earth‑moving equipment.

- Project timelines stretch from a few years to over a decade, with budgets ranging from tens of millions to several billions of pounds.

- Key success factors are rigorous risk management, community engagement, and skilled multidisciplinary teams.

Defining Heavy Civil Construction

Heavy civil construction is a branch of civil engineering that focuses on large‑scale public infrastructure projects designed to serve mass transportation, water management, or energy distribution needs. The term distinguishes itself from "light" civil work-like sidewalks, small retaining walls, or local utility upgrades-by the sheer size, cost, and societal impact of the projects.

Scope of Work: What Projects Qualify?

Below are the most common categories that fall under heavy civil:

- Highways and Expressways-multi‑lane roadways, interchanges, and associated bridges that handle tens of thousands of vehicles daily.

- Bridges-including suspension, cable‑stayed, arch, and beam bridges spanning rivers, valleys, or busy highways.

- Tunnels-underground passages for road, rail, or utility services, often bored through rock or built using cut‑and‑cover methods.

- Dams and Water Retention Structures-structures that store water for flood control, hydro‑electric power, or irrigation.

- Airports-runways, taxiways, terminals, and supporting ground infrastructure capable of handling commercial aviation traffic.

- Rail Networks-high‑speed lines, commuter rails, freight corridors, and associated stations and bridges.

- Port and Harbor Facilities-quays, container terminals, and dredging works that enable maritime trade.

Each of these categories involves extensive earthwork, structural engineering, and long‑term maintenance planning.

Heavy Civil vs. Light Civil: Key Differences

| Aspect | Heavy Civil | Light Civil |

|---|---|---|

| Typical Budget | £10million - £10billion+ | £10k - £1million |

| Project Duration | 2-15 years | Weeks-Months |

| Primary Funding | Government, PPP, Municipal Bonds | Private owners, Small‑scale public grants |

| Engineering Disciplines Involved | Civil, Structural, Geotechnical, Transportation, Environmental | Civil, Mechanical (often limited) |

| Regulatory Scrutiny | Extensive permitting, environmental impact assessments, public consultations | Minimal, local authority approvals |

Core Materials and Equipment

Heavy civil projects rely on a handful of high‑performance materials:

- High‑strength concrete-often > 60MPa for bridge decks and dam walls.

- Structural steel-used in girders, cable stays, and tunnel liners.

- Reinforced earth-for retaining walls and slope stabilization.

Equipment includes massive earth‑moving machines (draglines, excavators with 20‑m buckets), pile‑driving rigs, and specialized tunnel boring machines (TBMs) that can be over 12m in diameter.

Regulations, Standards, and Risk Management

Given the public‑funded nature, heavy civil must obey strict UK regulations:

- BS EN 1992 (Eurocode 2) for concrete design.

- BS EN 1993 (Eurocode 3) for steel structures.

- Environmental Impact Assessment (EIA) directives under the UK Planning Act.

- Health and Safety at Work Act (HSWA) plus Construction (Design & Management) Regulations (CDM2021).

Risk registers track geological surprises, cost overruns, and community opposition. Using MonteCarlo simulations for cost‑time modeling has become standard practice on £500million+ projects.

Cost and Timeline Realities

Budget overruns are common. The 2023‑2026 HS2 PhaseOne, a high‑speed rail line, initially forecast at £55billion, rose to over £70billion due to ground‑condition complexities and inflation in steel prices (up 22% YoY). A useful rule of thumb: add a 15‑20% contingency for unknown subsurface conditions.

Timeframes are driven by:

- Design & approvals (often 1‑3years).

- Site preparation and earthworks (6‑12months for major grading).

- Structural construction (2‑5years depending on project type).

- Testing, commissioning, and hand‑over (6‑12months).

Career Paths in Heavy Civil

Working on heavy civil projects requires a blend of technical and managerial skills. Typical roles include:

- Civil Engineer (design and analysis).

- Geotechnical Engineer (soil and rock assessments).

- Construction Manager (on‑site coordination).

- Project Controls Engineer (cost and schedule monitoring).

- Environmental Specialist (EIA compliance).

Many UK firms sponsor graduate schemes that rotate through design offices, site offices, and client liaison teams, offering a 3‑year fast track to chartered status.

Common Pitfalls and How to Avoid Them

- Inadequate ground investigations. Mitigate by commissioning full geotechnical bore‑hole programs before final design.

- Underestimating stakeholder impact. Conduct early community workshops and maintain a transparent communication plan.

- Supply‑chain bottlenecks. Pre‑qualify multiple material suppliers and include flex clauses in contracts.

- Regulatory delays. Align the project schedule with permitting calendars; allocate at least 12months for major environmental approvals.

Quick Checklist for New Heavy Civil Projects

- Define project scope and public benefit metrics.

- Secure funding agreement (government budget, PPP, or bond issuance).

- Commission comprehensive geotechnical and topographical surveys.

- Develop an EIA and obtain planning permission.

- Prepare a detailed risk register with cost contingency.

- Choose a lead contractor with proven heavy‑civil track record.

- Set up a CDM2021 compliant site management plan.

- Implement a BIM 360 model for design‑construction coordination.

Frequently Asked Questions

What distinguishes heavy civil from commercial construction?

Commercial construction focuses on private‑sector buildings like offices, malls, or hotels. Heavy civil, by contrast, delivers public‑use infrastructure-roads, bridges, tunnels, dams, and similar projects that serve a broader community.

Do heavy civil projects always require government funding?

Most are publicly funded, but many use public‑private partnership (PPP) models where private investors share risk and receive long‑term revenue streams (e.g., tolls or airport fees).

How long does a typical heavy civil project take?

Duration varies widely; a regional highway might finish in 3‑4years, whereas a major dam can span a decade or more, especially when phased construction and environmental monitoring are required.

What are the biggest environmental concerns?

Habitat disruption, watercourse alteration, air quality during construction, and carbon emissions from concrete and steel production. Robust EIA processes and mitigation measures (e.g., wildlife corridors, low‑carbon cement) are essential.

Which UK standards govern heavy civil design?

The primary references are Eurocode 2 (BS EN 1992) for concrete, Eurocode 3 (BS EN 1993) for steel, and the CDM2021 regulations for health‑and‑safety. Additional guidance comes from the Highways England Design Manual and the Environment Agency’s flood‑risk policies.