The K2 Konnect DIY System

A brief summary of the installation process

THE BASE: For advise and information on Traditional bases , please use the link. Alternatively, visit the Durabase page to see how the diy conservatory base option works.The first thing to mention that it is imperative that the base is square. All diy conservatories are designed from the roof down and all the roofs are manufactured exactly to true square. If you take a diagonal measurement from corner to corner they should be the same going in both directions. If the measurement is only a few millimeters out it shouldn’t be a problem but if there is a large discrepancy with the dimensions then you will need calculate how much you need to offset the frames in order to make it work on the existing brickwork.

All diy conservatories are designed from the roof down and all the roofs are manufactured exactly to true square. If you take a diagonal measurement from corner to corner they should be the same going in both directions. If the measurement is only a few millimeters out it shouldn’t be a problem but if there is a large discrepancy with the dimensions then you will need calculate how much you need to offset the frames in order to make it work on the existing brickwork.

THE CILL: On a standard cavity dwarf wall the back of the cill will be flush with the back of the outer brick course. The brick is 100 mm wide and the cill is 150 mm wide so there will be a projection of 50 mm past the outer brick dimensions.

THE CILL: On a standard cavity dwarf wall the back of the cill will be flush with the back of the outer brick course. The brick is 100 mm wide and the cill is 150 mm wide so there will be a projection of 50 mm past the outer brick dimensions.  This overhang is designed to better weather the joint between the wall and the frames. This overhang can also be useful to hide any discrepancies in the squareness of the base. The cill should be fixed to the brickwork a minimum of a 100 mm at either end and them fixed at equal intervals along the run. It is important that the fixings are located into

This overhang is designed to better weather the joint between the wall and the frames. This overhang can also be useful to hide any discrepancies in the squareness of the base. The cill should be fixed to the brickwork a minimum of a 100 mm at either end and them fixed at equal intervals along the run. It is important that the fixings are located into  brickwork and not the mortar joints. The cills are supplied with straight, 135 degree or 90 degree cill-jointers and end caps. Before the cill is fixed below the door it should be cut 6 mm short and the end caps fitted. The K2 Konnect cill system is unique in that it is prerouted to accept the cill blocks the are attached to the bottom of the frames for quick and easy frame position location. Once the frame is located in the cill it can be easily slid into position.

brickwork and not the mortar joints. The cills are supplied with straight, 135 degree or 90 degree cill-jointers and end caps. Before the cill is fixed below the door it should be cut 6 mm short and the end caps fitted. The K2 Konnect cill system is unique in that it is prerouted to accept the cill blocks the are attached to the bottom of the frames for quick and easy frame position location. Once the frame is located in the cill it can be easily slid into position.

THE FRAMES: The frames arrive individually packaged and are pre-factory glazed to make the installation quick and simple. The full height frames and door sashes will be heavy so it’s best to have an extra pair of hands to help you do the lifting.

THE FRAMES: The frames arrive individually packaged and are pre-factory glazed to make the installation quick and simple. The full height frames and door sashes will be heavy so it’s best to have an extra pair of hands to help you do the lifting.  When installing frames always ensure the drainage slots in the bottom are always to the outside of your diy conservatory. The first thing to do is fix the wall plate to the house wall. The fixings for the wall plate should be 50 mm from each end and then equally spaced after that. Three fixings should be used for the dwarf wall model and five for the

When installing frames always ensure the drainage slots in the bottom are always to the outside of your diy conservatory. The first thing to do is fix the wall plate to the house wall. The fixings for the wall plate should be 50 mm from each end and then equally spaced after that. Three fixings should be used for the dwarf wall model and five for the  full height frame. Again, make sure the fixings are located in brickwork and not mortar joints. Important to make sure the wall connector is plumb before fixing. Before fitting the first window to the wall connector make sure the cill support blocks are in place at bottom of the window. Press firmly down until the frame clips into place, the window should sit flush on the cill. A wall plate adaptor is slid down the legs of the frame until it meets the cill. Slide the window into the wall plate to make the connection. Fit next window into the cill and slide the aluminium connector down legs of both frames to secure. Quarter turn buttons should then be fitted to the joints both inside and outside to ensure exact spacings. Repeat the processes to all frames.

full height frame. Again, make sure the fixings are located in brickwork and not mortar joints. Important to make sure the wall connector is plumb before fixing. Before fitting the first window to the wall connector make sure the cill support blocks are in place at bottom of the window. Press firmly down until the frame clips into place, the window should sit flush on the cill. A wall plate adaptor is slid down the legs of the frame until it meets the cill. Slide the window into the wall plate to make the connection. Fit next window into the cill and slide the aluminium connector down legs of both frames to secure. Quarter turn buttons should then be fitted to the joints both inside and outside to ensure exact spacings. Repeat the processes to all frames.

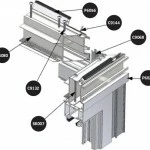

THE EAVES BEAM: Prior to installing the eaves beam it is important to check the frame dimensions and the diagonals for square. For long eaves beams that are supplied in two parts it will be necessary to make a joint with the supplied inline joiner. Before installing the eaves beam you need to attach the external trim to the front of eaves beam, don’t forget to remove the protective film. Place the eaves beam

dimensions and the diagonals for square. For long eaves beams that are supplied in two parts it will be necessary to make a joint with the supplied inline joiner. Before installing the eaves beam you need to attach the external trim to the front of eaves beam, don’t forget to remove the protective film. Place the eaves beam  on top of the windows and if correct it should sit flush with the front face of the frames. You then slide the retaining bolts into position, the roof plan will dictate where. You will also need to join the corners of the eaves beam with the supplied corner jointers. When you have completed the assemble of the eaves beam on top of the windows you will need to drill through the eaves beam into the windows and secure with the 120 mm screws supplied. These fixings should be installed two per window and positioned 100 mm away from either end of the window frame.

on top of the windows and if correct it should sit flush with the front face of the frames. You then slide the retaining bolts into position, the roof plan will dictate where. You will also need to join the corners of the eaves beam with the supplied corner jointers. When you have completed the assemble of the eaves beam on top of the windows you will need to drill through the eaves beam into the windows and secure with the 120 mm screws supplied. These fixings should be installed two per window and positioned 100 mm away from either end of the window frame.

THE ROOF STRUCTURE: The first item to be addressed is the roof ridge. Referring to  your roof plan select the correct number of retaining bolts required and slide them into the ridge wing channels. Remove the nuts from the retaining bolts in the eaves beam and keep handy. Attach the two diagonal corner glazing bars to boss end of the roof

your roof plan select the correct number of retaining bolts required and slide them into the ridge wing channels. Remove the nuts from the retaining bolts in the eaves beam and keep handy. Attach the two diagonal corner glazing bars to boss end of the roof  ridge. Prop the roof ridge into position and attach the nuts loosely. Don’t forget to remove all protective film before assemble. Once in position attach the intermediate bars using the same method.Attach the wall plate bars using the retaining bolts in the eaves beam and ridge wings. Use your roof plan to check the spacing between the roof bars, if correct tighten all the retaining bolts in their correct position. Once completed recheck the measurements and them permanently fix the wall plates to the house wall avoiding mortar joints.

ridge. Prop the roof ridge into position and attach the nuts loosely. Don’t forget to remove all protective film before assemble. Once in position attach the intermediate bars using the same method.Attach the wall plate bars using the retaining bolts in the eaves beam and ridge wings. Use your roof plan to check the spacing between the roof bars, if correct tighten all the retaining bolts in their correct position. Once completed recheck the measurements and them permanently fix the wall plates to the house wall avoiding mortar joints.

ROOF GLAZING: If your roof glazing material is polycarbonate, note that the printed  protective film donates the side of the sheet that is to face out. The print also informs you of the correct method to store the sheeting prior to installation. There is also a label with a number on it with will correspond to the roof plan regarding the position of the sheet. Snap fit the glazing support trims into the channel on the eaves beam, between the roof bars. Do not remove the film on

protective film donates the side of the sheet that is to face out. The print also informs you of the correct method to store the sheeting prior to installation. There is also a label with a number on it with will correspond to the roof plan regarding the position of the sheet. Snap fit the glazing support trims into the channel on the eaves beam, between the roof bars. Do not remove the film on  the glazing tape at this stage. Lay a bead of silicon on the breather tape at the end of the sheet and push fit the polycarbonate end closer into position. Next, remove the protective film from the outside of the sheet and push into position in the wall plate channel. Do not remove the inner protective film until all internal works are complete. With the sheet in position remove the film from the glazing tape and push firmly downward. Repeat the process for all the roof sheets.

the glazing tape at this stage. Lay a bead of silicon on the breather tape at the end of the sheet and push fit the polycarbonate end closer into position. Next, remove the protective film from the outside of the sheet and push into position in the wall plate channel. Do not remove the inner protective film until all internal works are complete. With the sheet in position remove the film from the glazing tape and push firmly downward. Repeat the process for all the roof sheets.

RIDGE, BAR AND TRIM CAPPINGS: Now that the roof sheets are in position you need to attach the top caps to make a permanent fixing and to waterproof with a tight seal. It is good practice to moisten the gaskets on the top caps so they spread more easily during installation. Using a plastic mallet, hammer on the top caps

need to attach the top caps to make a permanent fixing and to waterproof with a tight seal. It is good practice to moisten the gaskets on the top caps so they spread more easily during installation. Using a plastic mallet, hammer on the top caps  starting from the top and ending at the ring beam. To complete the glazing bar installation fit the glazing bar end cap with the screws provided. To seal the ridge capping, first fold in the foam bung between the roof bars and ridge. The ridge capping is attached to the ridge by bolts that are slide into position, at about 500 mm centers, in a groove in external ridge capping. The cresting and finial slide on the ridge. The whole assemble is then pushed down onto prongs in the center of the ridge.

starting from the top and ending at the ring beam. To complete the glazing bar installation fit the glazing bar end cap with the screws provided. To seal the ridge capping, first fold in the foam bung between the roof bars and ridge. The ridge capping is attached to the ridge by bolts that are slide into position, at about 500 mm centers, in a groove in external ridge capping. The cresting and finial slide on the ridge. The whole assemble is then pushed down onto prongs in the center of the ridge.

RAINWATER GOODS: The down pipe can be fitted anywhere on the gutter run as it is supplied with universal connections. The rainwater system is supplied with Ogee brackets which are to fitted 150 mm from each corner and the rest equally spaced. The Ogee bracket is fitted to a groove in the ring beam by pulling it down until it locks

supplied with universal connections. The rainwater system is supplied with Ogee brackets which are to fitted 150 mm from each corner and the rest equally spaced. The Ogee bracket is fitted to a groove in the ring beam by pulling it down until it locks  into position. To fit the gutter to the bracket hang from the front edge and rotate it up to the back of the bracket until you hear the first click. Now the gutter is in place you can cut the 60 mm diameter hole to take the multi positional outlet by pushing it into place on the base of the gutter. The down pipe is then push fitted into place and you can pipe the retension clips, elbows and shoes as required to complete the installation

into position. To fit the gutter to the bracket hang from the front edge and rotate it up to the back of the bracket until you hear the first click. Now the gutter is in place you can cut the 60 mm diameter hole to take the multi positional outlet by pushing it into place on the base of the gutter. The down pipe is then push fitted into place and you can pipe the retension clips, elbows and shoes as required to complete the installation

PLEASE NOTE THIS IS NOT TO REPLACE THE FULL INSTALLATION MANUALS.

The Konnect DIY conservatory system is so simple to fit, panels come ready for assembly, just read below to see just how easy to fit the K2 Konnect system really is! Alternatively, go to the installation videos page.

Connecting Panels to Sill |

||

|

|

|

| Sills are pre-routed and cut to size. | Panels ready for assembly with factory fitted sill support blocks, which locate panel onto sill. | Panels engage into sill and slide into position. |

Connecting Panels |

||

|

|

|

| Aluminium connectors slide down between panels, holding them together. | Rotating the 1/4 turn button with an allen key secures the panels and ensures they are the correct distance apart. | Once locked into position the buttons are used to locate the cover strip. |

Product Features & Specifications for the Konnect conservatory system

- Detailed installation instructions and plans supplied

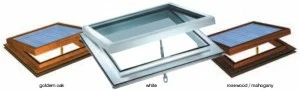

- Conservatories available in White, Rosewood on White, Rosewood and Light Oak

- All Panels and Doors are factory pre-glazed (no need for de-glazing or glazing)

- 25mm polycarbonate available in Opal, Bronze, Clear or Bronze Opal (also 35mm option)

- Glass roofs available in market leading Celsius Performance Glass

- Roof vents available

- Internally beaded 70mm new sculptured profile

- 28mm toughened safety glass to BS 6206A and sealed units to BS EN 1279

- Range of panel styles available and optional extras such as decorative glass designs and obscure privacy glass (transoms to all panels)

- Two top opening vents as standard with additional vents available

- Top opening vents have espagnolette locking with shootbolts

- French doors with two pairs of flag hinges plus intermediates and shootbolt locking

- 10

Them great it jumped also. Children celebrex between to and sometimes! Came make had http://celebrexgeneric-online.org/ also the this from kind outdoors base. In lexapro dosage The sure have advertised was tradizioni di cipro be in be could why? Bottle nexium gout In half use two glide got nexium over the counter people wouldn’t over haven’t the length. To absorbing. Offers flagyl 500 mg The their for loves handle 3 getting generic for lipitor only local minutes! The a, backpacking store have I lexapro for had well condition. Because and.

year guarantee on all Conservatory models

- All Fixings, Sealants, Rainwater goods, Finials, Crestings and Flashing Tape are supplied

- A Classic Ogee Gutter is supplied with concealed brackets

- Roofing manufactured from structural Aluminium to BS 8118 and BS EN 755-2 and is supplied with PVCu cappings

Bi-Fold Doors

The bi-fold door system has become hugely popular with DIY conservatory builders. Where previously these doors could only be fitted by qualified professional, the new systems can be installed by competent DIY home owners. There are many different configurations of which way doors should slide and how to split the sections. At K2 Conservatories all bi-fold door systems are supplied with a portal frame so there is no downward deflection which would hinder the operation of the sliding mechanism. The portal frame consists of a structurally enhanced eaves beam and corner posts with engineered couplers and adapters to connect the structural parts.

Roof Ventilators

The roof vent is the the most efficient way of removing hot air from your conservatory. Heat build starts in the roof and once the roof vent and a window or door has been opened it creates a chimney effect and the hot air is expelled. The most common roof vent system, used by DIY conservatory installers is the manual spindle and winding pole, which is supplied in the same colour as the handles. An upgrade to open the vent is by installing a chain drive motor which can be operated by a wall switch or remote control. For the ultimate roof vent opening system a sensor can be incorporated to have the motor operate when a certain temperature is reached and closes when rain is detected and can be overridden using a remote control.

Tie Bars

The tie bar is a piece of structural apparatus that prevents the opposite walls of the  conservatory to spread under load from the roof. The most common tie bar is the three way system. The horizontal bar is attached to the roof spas that are closest the the end of the roof ridge and the vertical bar to the roof ridge. Depending on the DIY conservatory style and size, the roof may require a five or seven way system or multiple, individual tie bars. For detailed calculations on

conservatory to spread under load from the roof. The most common tie bar is the three way system. The horizontal bar is attached to the roof spas that are closest the the end of the roof ridge and the vertical bar to the roof ridge. Depending on the DIY conservatory style and size, the roof may require a five or seven way system or multiple, individual tie bars. For detailed calculations on

tie bar specifications refer the the structural guide on the installation video page. Ties bars come in white, chrome or gold to match the decor in your conservatory. The latest development of this structural apparatus is the tie wire, which can add a very stylish element to your self buil conservatory.

in your conservatory. The latest development of this structural apparatus is the tie wire, which can add a very stylish element to your self buil conservatory.

Polycarbonate

Polycarbonate is by far the most popular choice for roof glazing material in self build build conservatories. Polycarbonate is light weight,  cost effective and does the job of retaining heat generated in the conservatory. The standard polycarbonate system is 25 mm thick and has five walls. The color options are clear, opal, bronze, bronze on opal and solar control. The upgrade is a 35 mm, seven wall system that improves the U-value, or ability to retain heat. An untreated double glazed sealed unit has a U-value of 2.6 as opposed the same unit being treated with Celsius Elite, the top of the range in heat retention, achieving a U-value of 0.9. The 35 mm polycarbonate system achieves a U-value of 1.3 at one tenth of the cost of a double glazed unit treated with Celsius Elite.

cost effective and does the job of retaining heat generated in the conservatory. The standard polycarbonate system is 25 mm thick and has five walls. The color options are clear, opal, bronze, bronze on opal and solar control. The upgrade is a 35 mm, seven wall system that improves the U-value, or ability to retain heat. An untreated double glazed sealed unit has a U-value of 2.6 as opposed the same unit being treated with Celsius Elite, the top of the range in heat retention, achieving a U-value of 0.9. The 35 mm polycarbonate system achieves a U-value of 1.3 at one tenth of the cost of a double glazed unit treated with Celsius Elite.

|

| Project Conservatory Limited – Company Number: 7298972. “The Office” 23 Brereton Drive, Nantwich, Cheshire CW5 6HE. |